Report "Possible processing techologies"

The report "Possible processing techologies" contains a description of potential processing technologies for the production of the selected product characteristics. Testing of the potential technologies includes the selection and evaluation of different technologies to achieve the appearance of products with specific properties in terms of optical, haptic and thermal properties (metallic appearance and tactile feel). This includes not only the processing technologies themselves but also the finishing technologies. The evaluation of these technologies has been carried out by partner companies and development institutions. In addition, we have involved external partners with expertise in the field of finishing, who have provided us with their expertise.

more...Report "Prototype tools"

The report "Prototye tools" includes the design and optimisation of the prototype tooling by our partner Hiebler GmbH, for the best material-technology combination. The engraving tool is equipped with interchangeable inserts, which allowed the production of different surface structures according to the different needs of the partners, in terms of the optical and haptic properties specified in WP1.

more...Report "Material characterization"

The report "Material characterization" includes the results of the characterisation of the selected materials identified in the state-of-the-art analysis of existing solutions in WP1. The report also includes descriptions of possible technologies for the development of the selected products.

more...Report "Prototypes"

The report "Prototypes" is based on the PolyMetal prototypes from the prototype mould. In line with the flexible nature of the mould (inserts with different roughnesses, PolyMetal and Interreg logos), we have produced different surface structures according to the different needs of the partners. These prototype products were also characterised and analysed by the design and marketing departments of the partner companies Gorenje and Intralighting. In addition, prototypes produced by Tehnomat and Tehnoplast Povše are presented.

more...PolyMetal Final Conference - Review

On 30th of September 2021 the "PolyMetal Final Conference: “Design flexibility of plastics, but look and feel like metals" took place at Montanuniversität in Leoben as a hybrid event.

Within the conference the benefits of crossboarder cooperation were highlighted. The partners presented their results gained within the project to master the challenges of developing and producing of polymer parts that look and feel like metal.

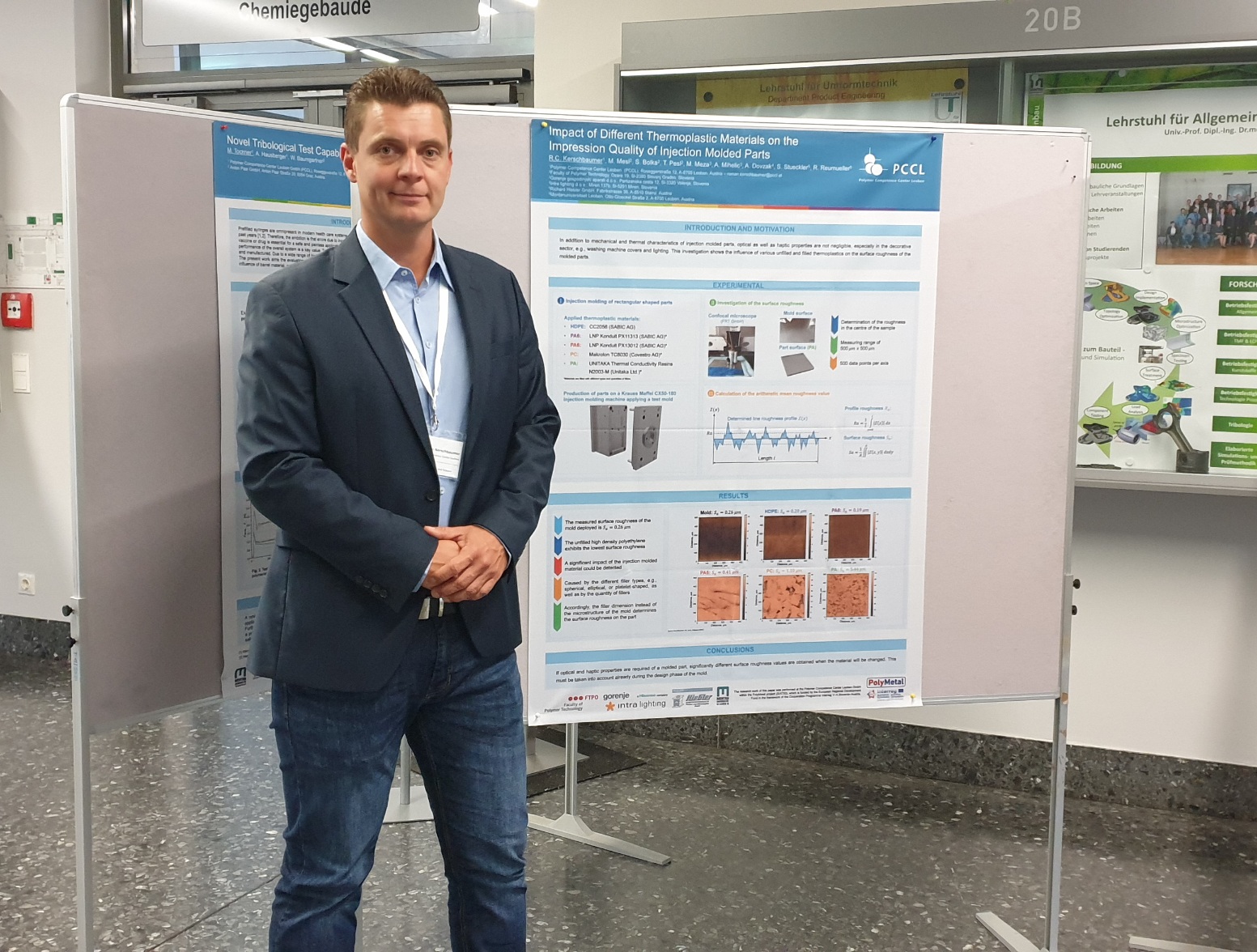

PolyMetal at 29. Leobener Kunststoffkolloquium

The 29th took place from September 15 to 16, 2021. The partners MUL and PCCL used the opportunity of the 50th anniversary of Polymer tecnic Leoben to draw the attention of the international participants from research and industry to the PolyMetal project. For example, a paper prepared by PCCL in cooperation with the partners as part of the project was published in the anniversary publication and an associated poster was presented at the poster exhibition. MUL invited the participants to the upcoming PolyMetal final conference on 30.09.2021.

PolyMetal results published in Open Access Journal MDPI Polymers

Scientific results achieved within the PolyMetal project have been published by the partners in the open access journal MDPI Polymers.

PolyMetal Conference 2021

Design flexibility of plastics, but look and feel like metals: PolyMetal successful crossboarder cooperation

The conference will take place on 30 September 2021 at the University of Leoben and will be held as a hybrid event.

more...PolyMetal at Plastic Gears Conference 2021

At the Plastic Gears Conference, Silvester Bolka / FTPO presented project PolyMetal. He shared PolyMetal research results at the hybrid event.

more...PolyMetal research results presented at PLASTIC GEARS CONFERENCE 2021

At the Plastic Gears Conference 2021, which will take place in Slovenj Gradec on 17-18 June at FTPO, Silvester Bolka/ FTPO will present results of research carried out by the project partners within the project PolyMetal. He will give a presentation on June 17th on "Effect of Compatibilizers on Surface Roughness, Mechanical and Thermal Properties of Thermoplastic Composites with High Thermal Conductivity".

more...PolyMetal Workshop: "Thermally conductive Materials & Testing of Thermal Conductivity" Review

On 10 February 2021, another online workshop on the topic "Thermally conductive materials & Testing of Thermal Conductivity" took place as part of the project PolyMetal. Due to the highly interesting topic, the workshop brought almost 70 participants from Slovenia, Austria, Italy, US and Germany with experts from companies 3M Advanced Materials Division, C3 Prozess- und Analysentechnik GmbH and The hydrogen and fuel cell center ZBT GmbH together. The participating project partners as well as representatives from research and industry used the opportunity to expand their knowledge through the presentations and discussions with the lecturing experts and to extend their cross-border network.

more...PolyMetal: Compounds with higher thermal conductivity

A video shows how compounds with higher thermal conductivity are produced within the project PolyMetal at FTPO in Slovenj Gradec.

more...PolyMetal: New Demonstrator Samples produced

On 15th October 2020 the partners of Hiebler (Stefan) and PCCL (Roman) met at FTPO (Maja, Teja, Silvo) in Slovenj Gradec. Stefan brought the at Hiebler newly created demonstrator tool inserts "PolyMetal Map" with 3 different surface roughness with him. With these new inserts we processed on the injection moulding machine of FTPO sample parts with different versions of PP with 50% of boron nitride (BN).

New PolyMetal showroom established at FTPO

In September 2020 the showroom of project PolyMetal was set up in the processing laboratory at FTPO.

The description of the achivements of PolyMetal project are described and the prototypes and demonstrators are exhibited.

The project PolyMetal project will be presented to all visitors from industry and research institutions.

If you are interested to visit us and get more informations about the project, please contact Maja Mesl maja.mesl@ftpo.eu or visit our website /polymetal-en/ and Linkedin group. https://www.linkedin.com/groups/13740430/

Research Activities

“PolyMetal's project team is currently working on the investigation of the surface roughness of injection molded parts.

The main research topic is whether the surface roughness of the injection molded part has the same roughness as the

surface of the injection mold applied. Another topic is, does the surface roughness of the molded parts change when

different thermoplastic polymers are processed or will it remain the same?”

PolyMetal Workshop: Thermally Conductive Materials Review

On June 18th 2020, the online workshop "Thermally conductive materials" took place within the project PolyMetal. Because of the Covid 19 situation, the event was organized as an online workshop via Microsoft teams. Despite severely restrictions, the workshop brought together almost 40 participants from Slovenia, Austria and Italy, with experts from the company COVESTRO from Germany. The workshop was mainly organized by the partners Montanuniversität Leoben and Faculty of Polymer Technology. Dr. Grote and Dr. Hungerland presented "New Ways to manage heat enabled by thermally conductive MAKROLON® polycarbonate - Macrolon® TC.

more...Visit of the K-Fair in Düsseldorf

Within the work package T2 the project partners of PolyMetal visited the K-Fair to inform themselves about the latest trends and available materials, technologies,... and to establish new contacts to companies and research institutions which are active in this field.

State of the art Reports on processing technologies and materials to achieve optical and haptic properties of Metals

In the first project year, the project PolyMetal mainly focused on research of possible processing technologies and materials, with which we could achieve polymers that look and feel like metal.

For knowledge transfer and know how building to other research institutions and companies, these reports: „State of the art Materials for increasing the thermal conductivity of plastics“ and „State of the art: Manufacturing processes for plastic components with metallic surfaces“ are available now.

PolyMetal Conference Review

On 13th of november 2018 the "PolyMetal Conference: “Look and Feel like Metals, but design flexibility of plastics: New aspects of polymers and metal‐polymer composites " took place at FTPO in Slovenj Gradec. The event was organized by the partners Faculty of Polymer Technology (FTPO, Slovenia) and Montanuniversität Leoben (MUL, Austria). The conference offered essential knowledge regarding fundamentals, visual and haptic aspects as well as thermal conductivity to master the challenges of developing and producing of polymer parts that look and feel like metal.

More than 70 participants from R&D and industry from Slovenia and Austria attended the event. They were very enthusiastic about the top quality presentations and also used the coffee breaks and lunch for intensive discussions with the experts and other participants to network.

more...Visit of the Fakuma in Friedrichshafen

The PolyMetal project team visited the FAKUMA fair in Friedrichshafen, where more than 2.000 exhibitors from the polymer industry were presenting their products, development, … The project partners were looking for ideas and materials, technologies needed for the research conducted within the project.

more...PolyMetal workshop of the consortium at HSR in Rapperswil Switzerland

On Thurstday, 18th of October 2018 the project team of PolyMetal met at IWK Institute (Institut für Werkstofftechnik und Kunststoffverarbeitung) at HSR in Rapperswill. Prof. dr. Frank Ehrig, the Chair of the Institute, presented the work of the Institute and its laboratories. The focus of his presentation was their work on the topic Polymer materials and technologies for products that look and feel like metal, which is the research topi cof the PolyMetal project. After the workshop with presentation and sharing of know-how, the project team had a consortium project meeting at the institute.

more...